|

|

|

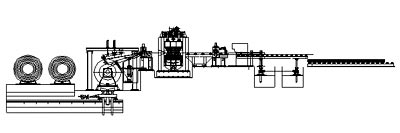

Cut-To-Length

|

| |

| IECO makes

world class Cut-to-Length Lines for both

H.R. & C.R. Coils, fully equipped Lines with Full Automatic & Semi-Automatic applications. |

| |

| Key Features: |

|

Accurate Measuring by servo system |

|

Feeding System for C.R.Line

Line is fitted

with 4 Hi 17 roll Precision Leveller & mech. |

|

Shearing Drop Stacker and Air Float stacker System |

|

|

| For

C. R. Coil Processing |

For

H.

R. Coil Processing |

Line Speed: Up to 85

mpm

Number of Cuts: Up to 30 Maximum /

min

Coil Width: 250 mm to 1250

mm

Coil Weight: 5 ton to 20

ton

Sheet Thickness: 0.25mm to

2mm

Cut Length : 100 mm to 4000

mm

Line is fitted with Paper Winder & Vinyl Applicator System |

Line Speed: 20 mpm to 45

mpm

Number of Cuts: Up to 25 Maximum /

min

Coil Width: 900 mm to

1800

mm

Coil Weight : 10 ton to 30

ton

Sheet Thickness: 12mm

Maximum

Cut Length : 500 mm to 7000 mm |

|

Terms details: mpm: Meter per Minute |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

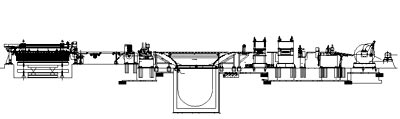

| Roll Forming Line |

| |

| IECO

makes world class Roll Forming Line for

H.R., C.R / GP Coils, fully equipped Lines with Full Automatic & Semi-Automatic applications. |

| |

| Key

Features: |

|

Cut Length Feed System or |

|

Cut Length Feed System or coil feed system

Line is fitted with

Precision Leveller and profile shear

Drop Stacker with Air Floating System for C.R.Line. |

|

In Line Notching & Punching System. |

|

With High precision grade Tooling

Spray type Force Coolant System

Logo Printer |

|

| For

C. R/GP/Color Coated Coil Processing |

For

H.

R. Coil Processing |

Line speed:

Up to 75 mpm

Number of Cuts: Up to 25 / min

Coil width: Up to 1250 mm

Coil Weight: Up to 23 ton

Sheet Thickness: 0.3mm to 1.5mm

Cut length : 4000 mm maximum |

Line Speed : Up to 25 mpm

Number of Cuts: Up to 18 Maximum / min

Coil Width: Up to 1500

mm

Coil Weight: Up to 25

ton

Sheet Thickness: Up to 4mm

Cut Length : 8000 mm

Maximum

Sheet Thickness: 2mm to 4mm Maximum |

|

Terms details: mpm: Meter per Minute |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

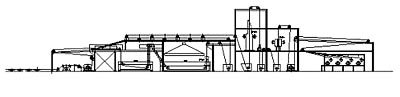

| Continuous

Pickling Line |

| |

| IECO

makes world class Pickling Line for

H.R. Coils, fully equipped with Full Automatic & Semi-Automatic applications. |

| |

| Key

Features: |

|

Granite Tiles laying in Acid Tank. |

|

FRVE acid storage / re-circulation tank

Shallow Push Pull System. |

|

Hydraulically Expand / Collapse Uncoiler & Recoiler |

|

Sheet Edge Trimmer |

|

Line is fitted with Oiling Roll |

|

Acid Proof Fume Exhaust System |

|

Acid Proof Pipe Line & Pumpsfor Acid Circulation |

|

Line is fitted with Graphite Heat Exchangers |

|

| |

| For

H. R. Coil Processing |

Line speed: Upto 90 mpm

Coil width: Upto 1250 mm

Coil Weight: 25 ton maximum

Strip Thickness : 3 mm maximum |

|

Terms details: mpm: Meter per Minute |

|

|

|

|

|

|

|

|

|

|

|

| High Tensile Strapping

Line |

| |

| IECO

makes world class High Tensile Strapping Line for

C.R.. Coils , fully equipped Lines with Full Automatic & Semi-Automatic applications. |

| |

| Key

Features: |

|

Heating of strips are done electrically in line

Color coating arrangement |

|

Line is equipped with cancellation unit / Zero potential unit

Steering Rolls. |

|

Long Length Looping Accumulators |

|

Multi Take-up units |

|

Logo Printer. |

|

|

| For

C. R. Coil Processing |

Line Speed

:40

mpm

Number of Strips : 12 Nos. Maximum (Width as per IS Standard)

Strip Thickness : As per Standards.

Number of Take-up units : 12 Re-Coiler Arrangement

Strips specification may change with respect to requirements. |

|

Terms details: mpm: Meter per Minute |

|

|

|

|

|

|

|

|

|

|

|

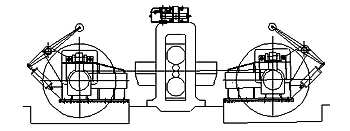

| Cold Rolling

Mill |

| |

| IECO

makes world class Narrow Cold Rolling Mill for

H.R Coils, fully equipped Lines with Full Automatic & Semi-Automatic applications. |

| |

| Key

Features: |

|

Reversible Type |

|

Pressure adjustment by screw shaft system through reducer gears |

|

Jet type Force Coolant System |

|

Digital Thermometer |

|

Gauge Controlling Unit |

|

Hydraulically Operated Roll Change Trolley |

|

Tension Reel exp/coll & Gripper Hydraulic operated. (Design I) |

|

Solid Drum Type Coiling System with separate payoff unit (Design II) |

|

|

| For

C. R. Coil Processing |

Line Speed : Upto 500

mpm

Coil width : Upto 600

mm

Coil Weight : Upto 10

ton

Input Coil Thickness: 2.5mm

Maximum

Output Coil Thickness: Maximum

reduced output: 0.2mm < 0.25mm

+

Unit have Digital / Clock type Indicators fitted on screw downs |

|

Terms details: mpm: Meter per Minute |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|